My Work

Autodesk Inventor Product Development

Milk Heater Design

Portfolio

I collaborated on updating a milk dispensing machines' .stp model. The update transitioned the prototype to production model. Here the tools I used to complete the update:

Hydraulic systems, Inventor tube and pipe environment.

Electronic design, Inventor cable and harness environment.

Parameter driven adaptive modelling.

Materials and properties management.

Lighting and environment settings for high quality photorealistic renders.

Assembly management of components and subassemblies in meaningful structures for producing bill of materials and assembly drawings

I designed a food grade milk heater to deliver coffee milk at 1L/min at 65 degrees. This was achieved in these key stages:

Preliminary research leading into material selection and power requirements.

CAD design with manufactuability in mind.

Local manufacturing by utilizing 3D printed molds for sand cast aluminium construction.

3D printed and plasma cut custom coil winding jig to craft the stainless steel coils for the precast assembly.

Spout Design

I redesigned the prototype spout so that the dispensed milk exits the machine smoothly without creating additional bubbles. This was accomplished by transitioning the small inner diameter of the tube to a larger diameter. In addition to this, I redirected the stream flow into itself such that the velocity of each smaller stream faced an equal opposing stream. These two changes created a solution to the dispense bubble problem. The laminar flow created by the new spout can be seen in the video. The spout has since been resin printed in a heat treated food grade resin for the production machine.

Drafting

I am highly proficient at creating engineering drawings. The images below are various sheets from a collection of drawings I drafted to convey the manufacturing process of a machines' sub-assemblies.

Controller Design

Heater Standby Controller

I made an open loop heater controller for when the machine is in standby mode. The controller calculates the amount of thermal energy required to reach the heater standby setpoint based on a simplified heater model developed in MATLAB. The operation of the standby controller is demonstrated in the video.

Beverage Temperature Controller

I developed a feedback controller to reach a desired beverage temperature. The controller error is the temperature measured at the spout. Control action was taken by changing the flow rate of the milk passing through the heater. I implemented this controller in C++ using Brett Beauregard's PID library.

Other Controllers

Volumization feedback controller: By measuring the flow rate before and then after air is introduced into the milk stream, the amount of milk volumization can be measured. A simple controller changes the amount of 'open' an air solenoid is such that a set percentage volumization is achieved.

Texture feedback controller: The system pressure should be maintained at 6.5 bar to ensure tight bubbles are formed in the milk. A controller changes the amount a restriction valve is open so that a constant pressure is maintained.

Personal Projects

Portfolio

Plasma Cutter

I made a DIY CNC plasma cutter; its operation can be seen in the video. Last semester break, I implemented a torch height controller (THC) using the electronics shown in the first photo below. The THC reads the voltage of the plasma arc as it corresponds to a distance. Therefore, maintaining a constant voltage corresponds to a constant height from the workpiece. The voltage is regulated by adjusting the Z stepper motor in a closed loop system. Keeping the height of the plasma arc throughout a cut has greatly improved the part quality. This project has been good for leaning some machining and computer aided manufacturing through Fusion360 CAM.

University Projects

Portfolio

Brushed DC motor

Walking Robot

Warehouse Robot

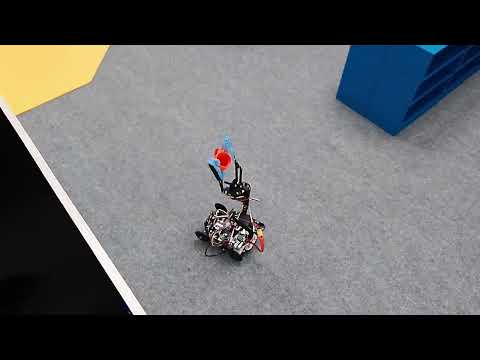

I made a walking robot with FDM 3D and resin printed parts on a steel frame. The robot converts rotation from one motor into walking movement through the use of slider cranks and four bar linkage mechanisms.

I collaborated in the design and construction of a brushed DC motor. Learning about motors was very insightful. I also learned about working as a group since this motor had to be improved over the design cycle. The process was ultimately satisfying since the motor ran efficiently.

I collaborated in the design and construction of a mock warehouse robot. This taught me about state machines and broadly how to tackle design challenges for given requirements. I developed the mobility and item collection subsystems. These systems were integrated by creating python libraries that allowed various movement and collection commands to be called by the navigation subsystem. I collaborated with my teammate to implement these libraries so the robot could complete its pick and place goals.

Software Skills

Davinci Resolve

LTspice

Ansys

Inventor

Photoshop

Illustrator

MATLAB

Simulink

Arduino

C++

© 2025 Joel